SUD AERO,

Expert Group in Aerospace Assembly

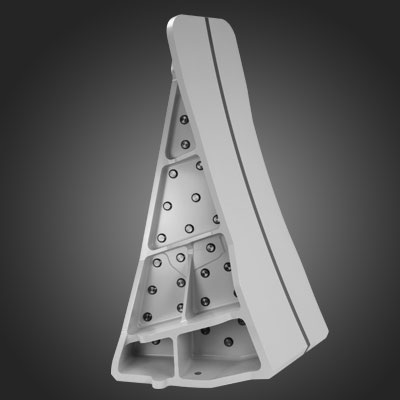

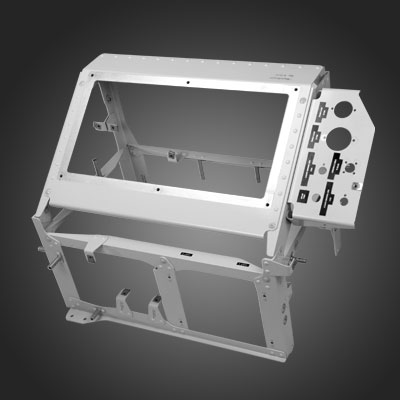

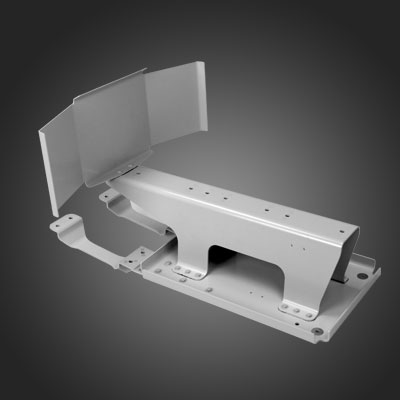

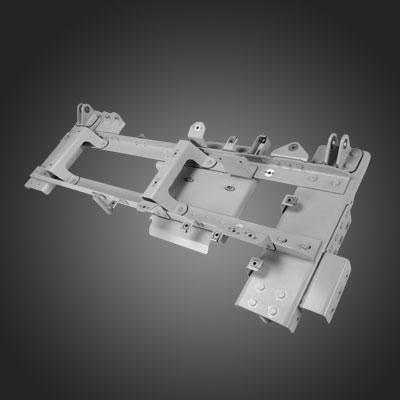

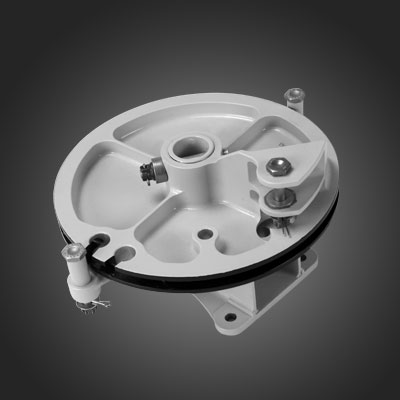

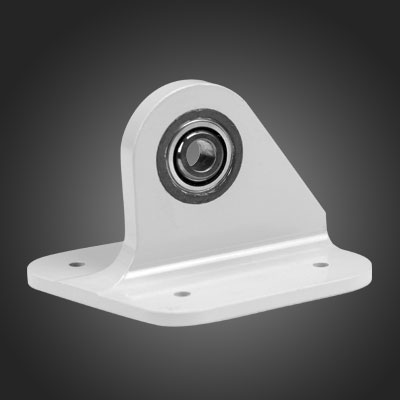

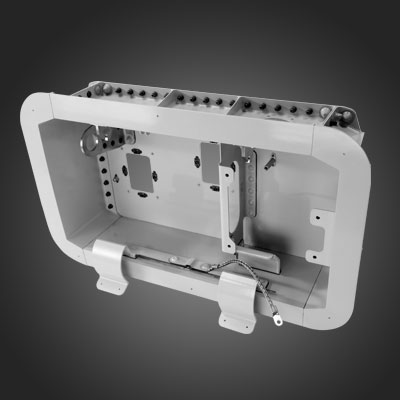

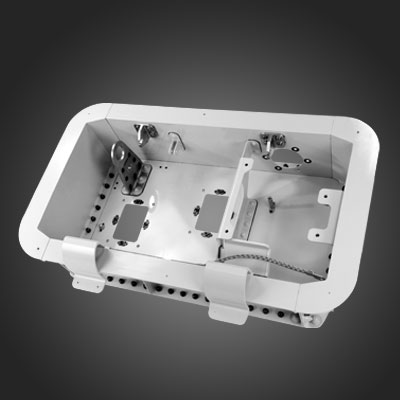

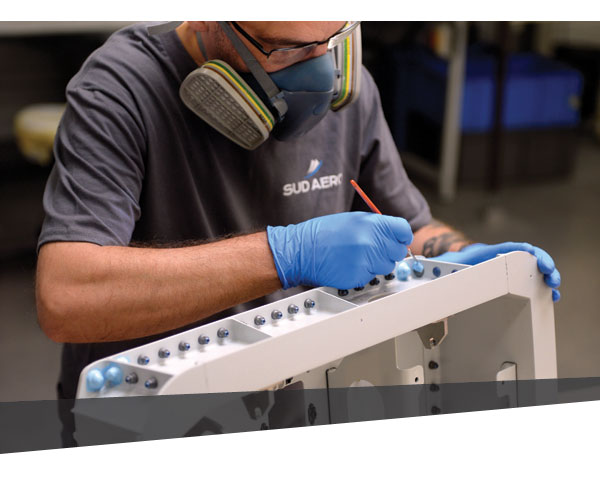

SUD AERO’s assembly site is based in Merville and covers 3,500m². It employs a team of 75 people dedicated to structural assembly. These highly experienced teams master all the techniques of riveting, tightening, crimping, inserting and sealing. They are capable of carrying out airtight fittings on all Airbus programmes.

This aircraft assembly department is also scalable, in order to enable SUD AERO’s customers to sub-contract part of their production activities at a given period. All the parts and assemblies produced by SUD AERO are delivered from the Merville, the Group’s logistics hub.

ASSEMBLY ACTIVITY

PRODUCTION SITE OF MERVILLE (31)

SUD AERO integrates the 4 major professions

relating to the manufacturing

of sub-assemblies for the aerospace sector

“ Our Ambition : ensuring high-quality production for the aerospace industry…

…combined with responsive, efficient and reliable customer support”

Guillaume Assorin, General manager

CERTIFICATIONS OF SUD AERO GROUP

Assembly

Human resources

SUD AERO has been satisfying its customers’ needs for more than 20 years. In the field of aircraft assembly, the expertise and commitment of SUD AERO’s staff enables the Group to provide its customers with extremely high quality production.

In order to maintain this high quality, SUD AERO provides ongoing training to all its employees in their respective professions.

Special processes

Aerospace assembly

As part of its aerospace Assembly activity, the SUD AERO Group provides its customers with a range of special processes for new aircraft programmes, such as the A350. You can consult the complete range of the Group’s special processes on the Special Processes page.

| RÉFÉRENCE | DÉNOMINATION |

|---|---|

| ADET0082 | APPLICATION OF SEALANTS |

| ADET0173 | INSTALLATION OF TIGHT FIT BUSHES |

| ADET0187 | WET INSTALLATION OF FASTENERS |

| ADET0191 | INSTALLATION OF BALL BEARING, SPHERICAL BEARING AND BUSHING BY STAKING |

| AIPS01-01-004 | INSTALLATION OF SOLID RIVETS |

| AIPS01-02-003 | PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING |

| AIPS01-02-006 | INSTALLATION OF LOCKBOLTS PULL AND STUMP TYPES |

| AIPS01-02-008 | TORQUE TIGHTENING OF SCREWS, BOLTS AND NUTS |

| AIPI01-02-013 | INSATALLATION OF BLIND BOLT “Pull-type” |

| AIPS01-02-017 | GENERAL ASSEMBLY AND INSTALLATION OF FASTENERS |

| AIPS01-02-019 | INSTALLATION OF BUSHES, SHRINK AND PRESS FIT |

| AIPS01-02-022 | INSTALLATION OF PARALLEL SHANK THREADED FASTENERS |

| AIPS03-03-012 | INSTALLATION OF BEARING, SPHERICAL BEARING AND BUSHES BY SWAGING |

| AIPS03-03-014 | COLD BONDING OF BUSHES, BALL BEARINGS, SPHERICAL BEARING |

| AIPS05-05-001 | SEALING OF AIRCRAFT STRUCTURE |

| AIPS05-05-006 | APPLICATION OF NON HARDENING JOINTING COMPOUNDS |

| AIPS05-05-008 | APPLICATION OF LOW ADHESION SEALANTS |

| AIPS06-01-004 | MECHANICAL SURFACE PREPARATION OF NON STRUCTURAL ADHEREND PRIOR TO ADHESIVE BONDING |

| AIPS06-02-002 | NON STRUCTURAL ADHESIVE BONDING |

| AIPS07-01-006 | ELECTRICAL BONDING |

| ADET0078 | STRUCTURAL RIVETING |