SUD AERO,

Expert Group in Aerospace sheet-metal work

SUD AERO’s sheet-metal production site is based in Lespinasse and covers 2,500m². It employs a team of 25 qualified and/or certified people.

The aerospace sheet-metal production site is equipped with a TIG welding robot and integrates the following skills:

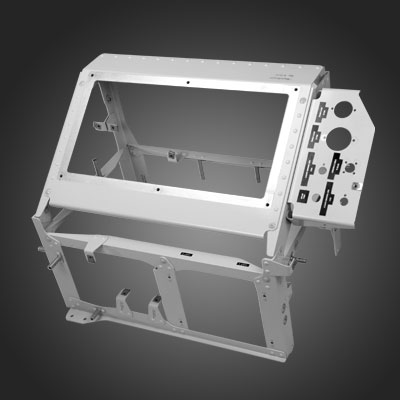

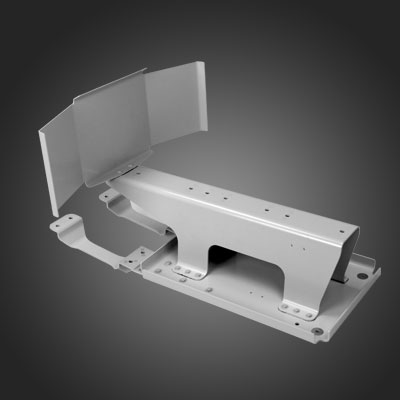

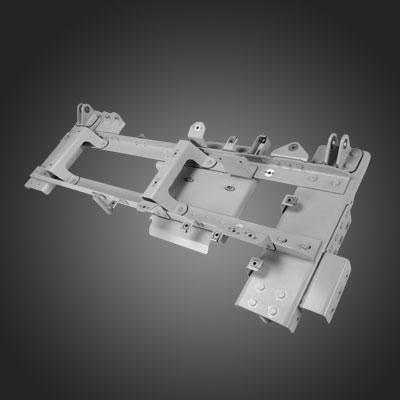

SHEET-METAL WORK ACTIVITY

PRODUCTION SITE OF LESPINASSE (31)

SUD AERO integrates the 4 major professions

relating to the manufacturing

of sub-assemblies for the aerospace sector

“ Our Ambition : ensuring high-quality production for the aerospace industry…

…combined with responsive, efficient and reliable customer support”

Guillaume Assorin, General Manager

CERTIFICATIONS OF SUD AERO GROUP

Sheet metal work

Industrial Facilities

To perform its aeTo perform its aerospace sheet-metal activity, SUD AERO has the following industrial tools:rospace sheet-metal activity, SUD AERO has the following industrial tools:

Special processes

Aerospace sheet-metal work

As part of its aerospace Sheet-Metal work activity, the SUD AERO Group provides its customers with a range of special processes for new aircraft programmes, such as the A350. You can consult the complete range of the Group’s special processes on the Special Processes page.

| RÉFÉRENCE | DÉNOMINATION |

|---|---|

| ADET0074 | GENERAL REQUIREMENTS ON WELDING (ALL MATERIALS) |

| ADET0203 | TIG WELDING |

| ADET0262 | REPAIR OR REWORK OF SHEET METAL PARTS BY MANUAL TIG WELDING |

| AIPS01-04-001 | GENERAL REQUIREMENTS FOR WELDING AND ALLIED PROCESSES |

| AIPS01-04-008 | TUNGSTEN INERT GAS (TIG) WELDING OF METALLIC MATERIALS |

| AIPS04-00-000 | HEAT TREATMENT OF METALLIC MATERIALS – GENERAL |

| AIPS04-01-001 | HEAT TREATMENT OF ALUMINIUM ALLOYS PARTS |

| AIPS03-09-001 | LASER CUTTING OF STEEL, TITANIUM, AND NICKEL ALLOYS |

| AIPS03-09-002 | LASER BEAM CUTTING OF ALUMINIUM ALLOYS |

| EN 2002-1 | TENSILE TESTING AT AMBIANT TEMPERATURE |