SUD AERO,

Expert Group in Machining

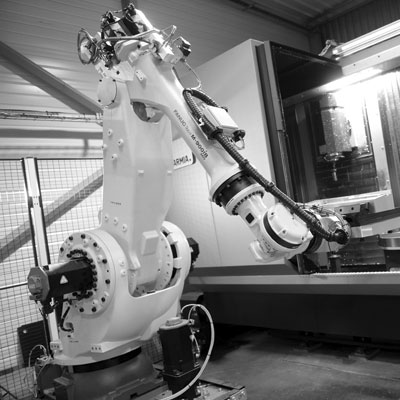

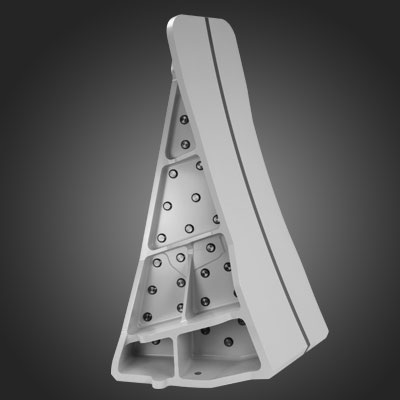

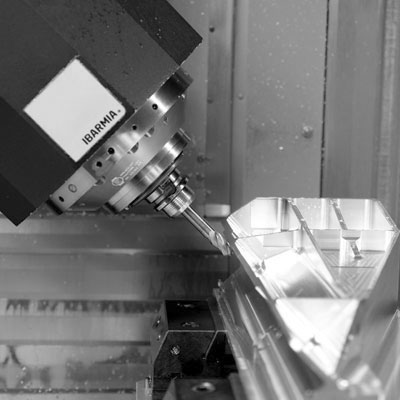

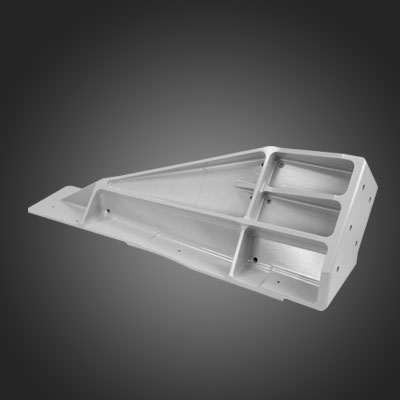

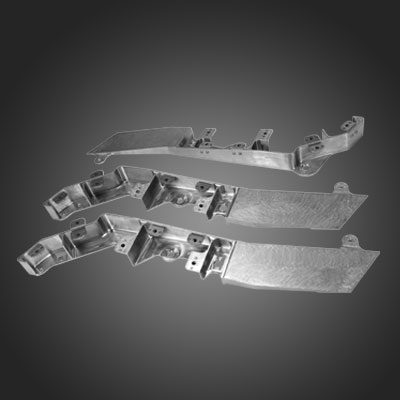

SUD AERO’s machining site is based in Saint-Alban and covers 5,000m². It employs a team of over 40 people. With 3 programmers at the service of the customers’ design offices and 17 experienced operators of 3-, 4-, and 5-axis machining centres, the Group is able to work on parts of up 2 meters in 5 axes.

With its highly qualified teams and state-of-the-art industrial facilities, the SUD AERO aerospace Machining site works on light alloys, such as aluminium and lithium, as well as hard alloys such as steel or titanium.

Autonomous production

of small and large series

production runs

The SUD AERO Group is recognised in the aerospace sector for its responsiveness and versatility as regards the production of prototype parts, the validation of operating processes before the launch of mass production runs and the optimisation of production flows.

SUD AERO places its expertise at its customers’ service by proposing an ever-increasing capacity in the fields of small and large series production runs, in particular on its new site aerospace machining site in Saint-Alban.

The Group is constantly seeking to optimise its mass production costs, particularly through the installation of new automated machining centres with pallet changers.

MACHINING ACTIVITY

PRODUCTION SITE OF SAINT-ALBAN (31)

SUD AERO integrates the 4 major professions

relating to the manufacturing

of sub-assemblies for the aerospace sector

“ Our Ambition : ensuring high-quality production for the aerospace industry…

…combined with responsive, efficient and reliable customer support”

Guillaume Assorin, General Manager

CERTIFICATIONS OF SUD AERO GROUP

Machining

Industrial facilities

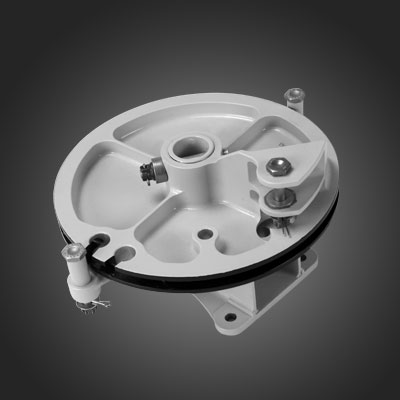

To perform its aerospace machining activity, SUD AERO has the following industrial tools:

Special processes

Aerospace machining

As part of its aerospace Machining activity, the SUD AERO Group provides its customers with a range of special processes for new aircraft programmes, such as the A350. You can consult the complete range of the Group’s special processes on the Special Processes page.

| RÉFÉRENCE | DÉNOMINATION |

|---|---|

| ADET0164 | FINISHING OF HARD METAL PARTS (BREAKING OF SHARP EDGES OR RADIUSING) |

| ADET0223 | FINAL ROUTING OF ALUMINIUM ALLOYS SHEETS |

| AIPS03-03-006 | WATER JET CUTTING |

| AIPS03-11-003 | DEBURRING AND MANUAL REWORK OF METALLIC COMPONENTS |

| IGC04-25-100 | METALLIC ELEMENTS LIQUID PENETRANT INSPECTION |

| IGC04-25-101 | FLUORESCENT DYE PENETRANT INSPECTION ALLOWED MATERIALS |

| IGC04-25-102 | VISUAL INSPECTIONS UNDER ULTAVIOLET RADIATION |

| AITM 1-0070 | SURFACE ROUGHNESS MEASUREMENTS USING SURFACE STYLUS METHOD |

| AITM 6-1001 | PENETRANT TESTING |

| AITM 6-6004 | DETERMINATION OF ELECTRICAL CONDUCTIVITY OF ALUMINIUM ALLOYS BY EDDY CURRENT METHOD |

| ISO 6506 | BRINELL HARDNESS |

| ISO 6508 | ROCKWELL HARDNESS |

| ISO 9227 | CORROSION TESTS IN ARTIFICIAL ATMOSPHERES – SALT SPRAY |